ADVANTAGES

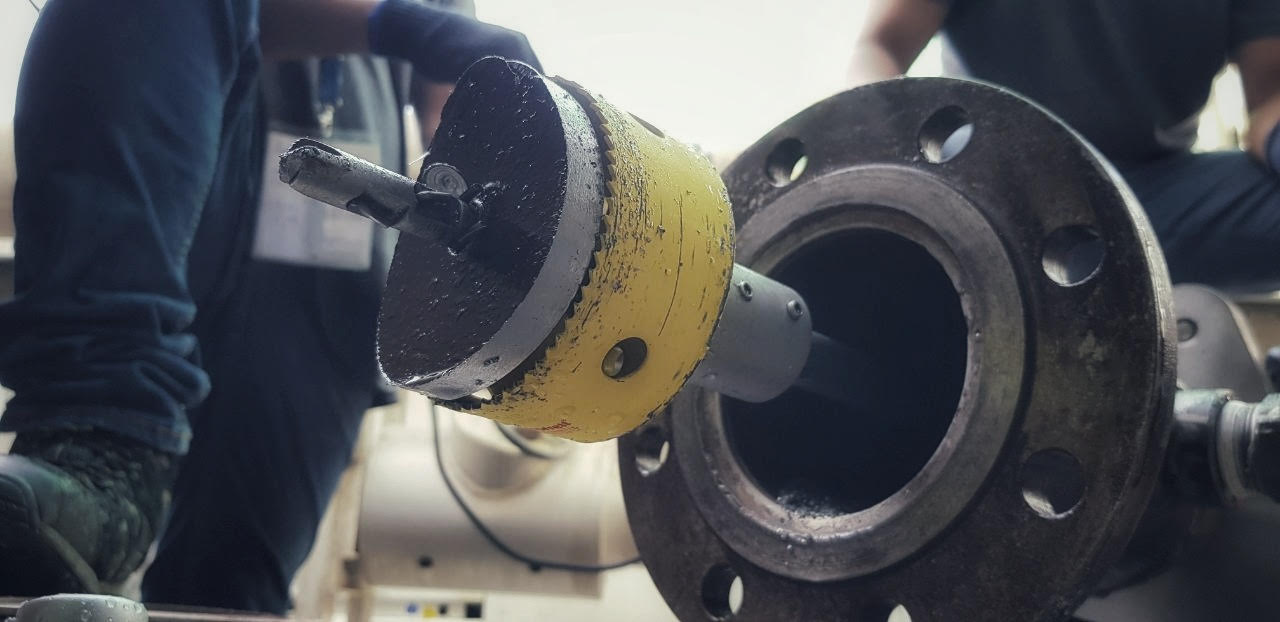

Minimal Interruption

Hot tapping enables you to make repairs or modifications to a pipeline without shutting it down completely, which minimizes disruption to operations.

Time-Saving

Hot tapping enables you to make repairs or modifications while the pipeline or system remains in operation, which can save time and reduce downtime.

Increased Safety

Hot tapping eliminates the need to de-pressurize and drain the pipeline or system, which can increase safety by reducing the risk of accidents and spills.

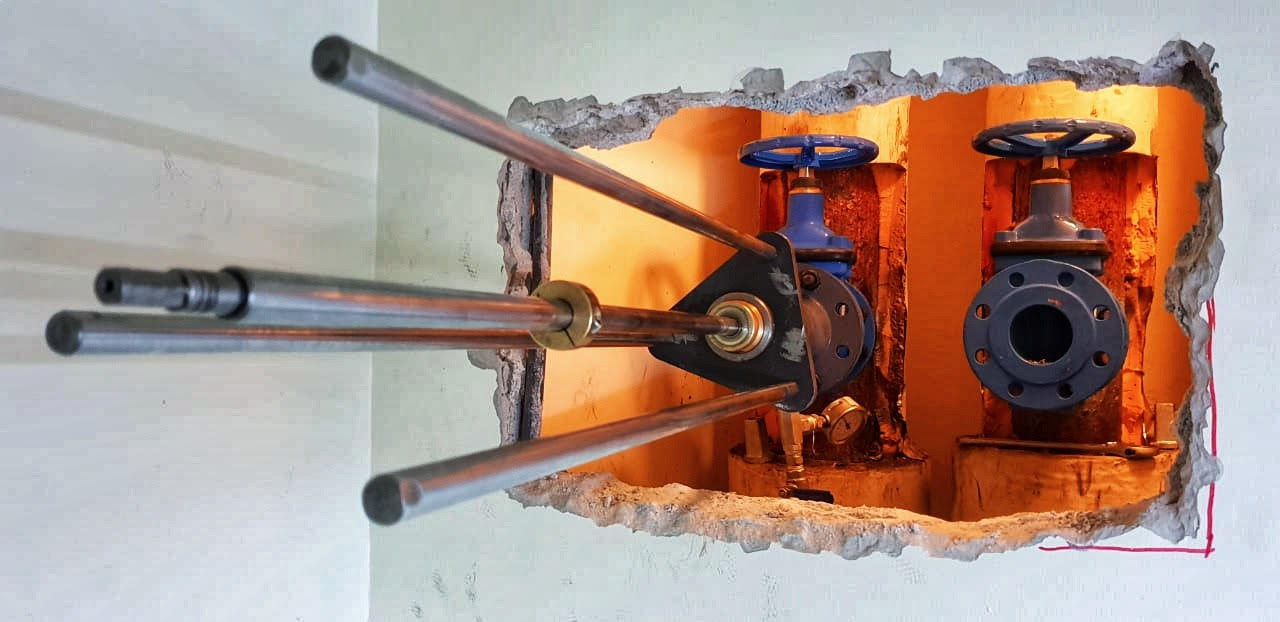

Versatility

Hot tapping can be used on a wide range of pipelines and systems, including water, gas, oil, and chemicals, making it a versatile repair and modification technique.

Cost-Effective

Hot tapping is often more cost-effective than shutting down a pipeline or system, draining it, and then making repairs or modifications.